Siemens TC HEP

Siemens Healthineers has commissioned an innovative campus for health care research in the town of Forchheim, near Nuremberg. PORR Industriebau is the full-service contractor for the “Technology Center for High-Energy Photonics”, or TC HEP, and pde is responsible for the BIM coordination of this complex building and is providing support for the LEED Silver building certification process.

Client

SIEMENS Healthineers; PORR Industriebau (pde employer)

pde service period

12/2019 - 12/2022

Work stages

Work stages 3+4: BIM management and LEAN services, sustainability and support for building certification (LEED Silver); work stage 5 (execution planning) and work stages 6-8 (execution) BIM management

Location

Forchheim near Nuremberg/Erlangen

Scheduled completion

12/2022

Service areas

BIM, sustainability

Dimensions

Total GFA: 54,786m², length 203m, width 63.48m, height 29.07m, for 450 employees; production facilities: 45,821m², 6 floors, 8 gates; office: 17,597m², 7 storeys; canteen: 368m², 96 seats

Certification

LEED Silver

Coordinating a complex project organisation

The “Technology Center for High-Energy Phototonics”, or TC HEP, is part of the new Siemens Healthineers Campus in Forchheim and one of Siemens Healthineers’ biggest investments, with a total volume of around 350 million euros. The centre contains the research and development department for computer tomography and x-ray applications. The complex technology requires its own building, which is connected to the centre. Technological data and information are processed in the adjoining offices.

PORR has a large, diverse project team coordinating all the internal and external parties involved in the planning and execution of the project.

PORR Industriebau was commissioned as full-service contractor from the preliminary design stage, which began at the start of 2020 and received support from LEAN management during this work stage, and from pde during the LEED building certification process. A short pre-construction stage was followed execution planning in October 2020. Execution began a short time later and is scheduled for completion by 2022. The BIM Excellence department at pde is responsible for BIM management across all the commissioned work stages.

Top level BIM coordination

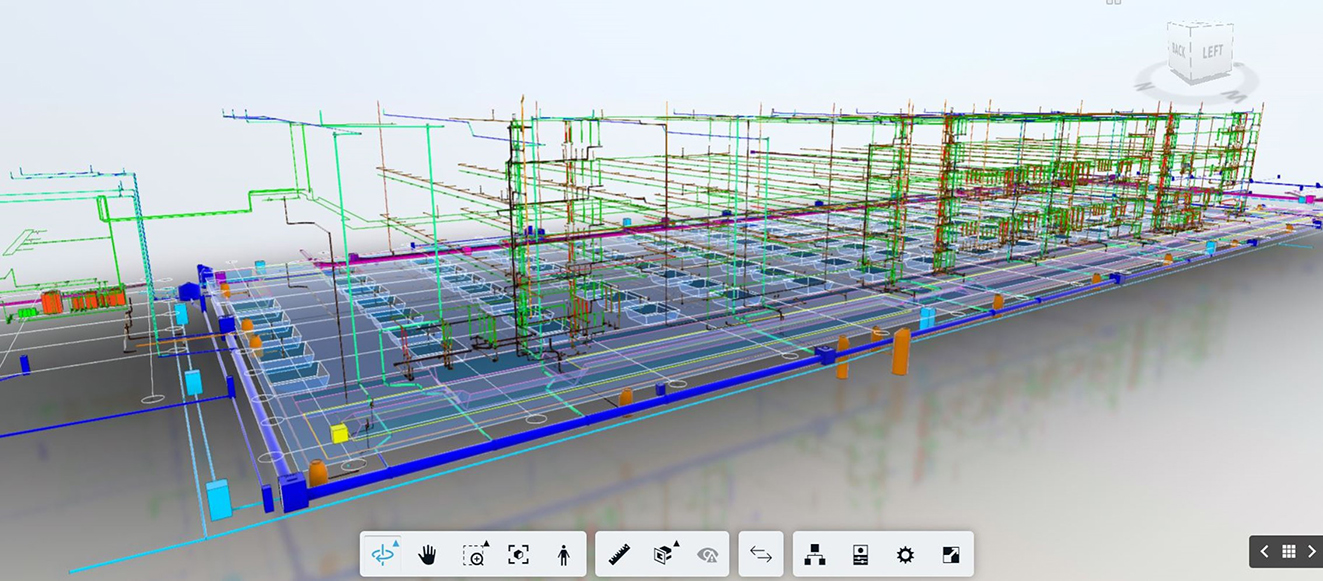

Siemens Healthineers’ primary goal is to provide targeted access to information from the BIM model across all project stages. This information is to be used in particular for building operations and facility management. These implementation goals are brought into line with PORR’s working methods in a 200-page BIM execution plan, which is a type of specification sheet for BIM planning.

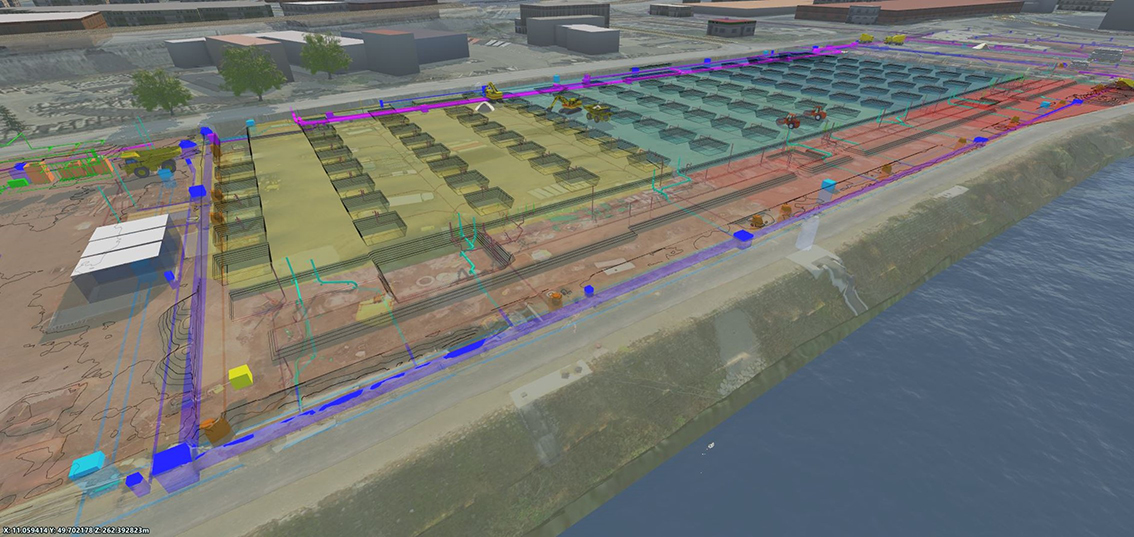

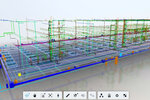

Up to 40 project participants from all trades and functions come together at the weekly BIM coordination jour fixe, which is moderated by the BIM management team, to discuss planning, content and technical issues in the framework of the BIM methodology.

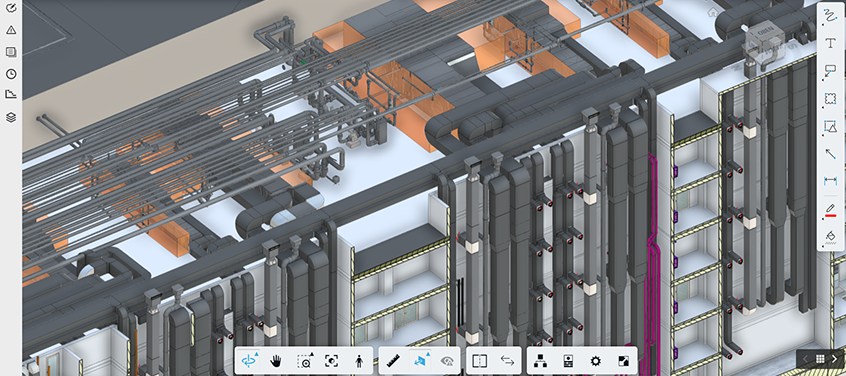

The BIM model landscape consists of around 20 submodels, which are created by the specialist planning departments and then compiled by the BIM management team. The BIM management team regularly checks the submodels for collisions during weekly data drops.

A CDE (common data environment) is used to manage the BIM models, the BIM documents, and other relevant BIM planning data. The environment enables around 80 participants to work on a shared BIM data model via multiple authorisation levels, while complying with extensive data protection requirements.

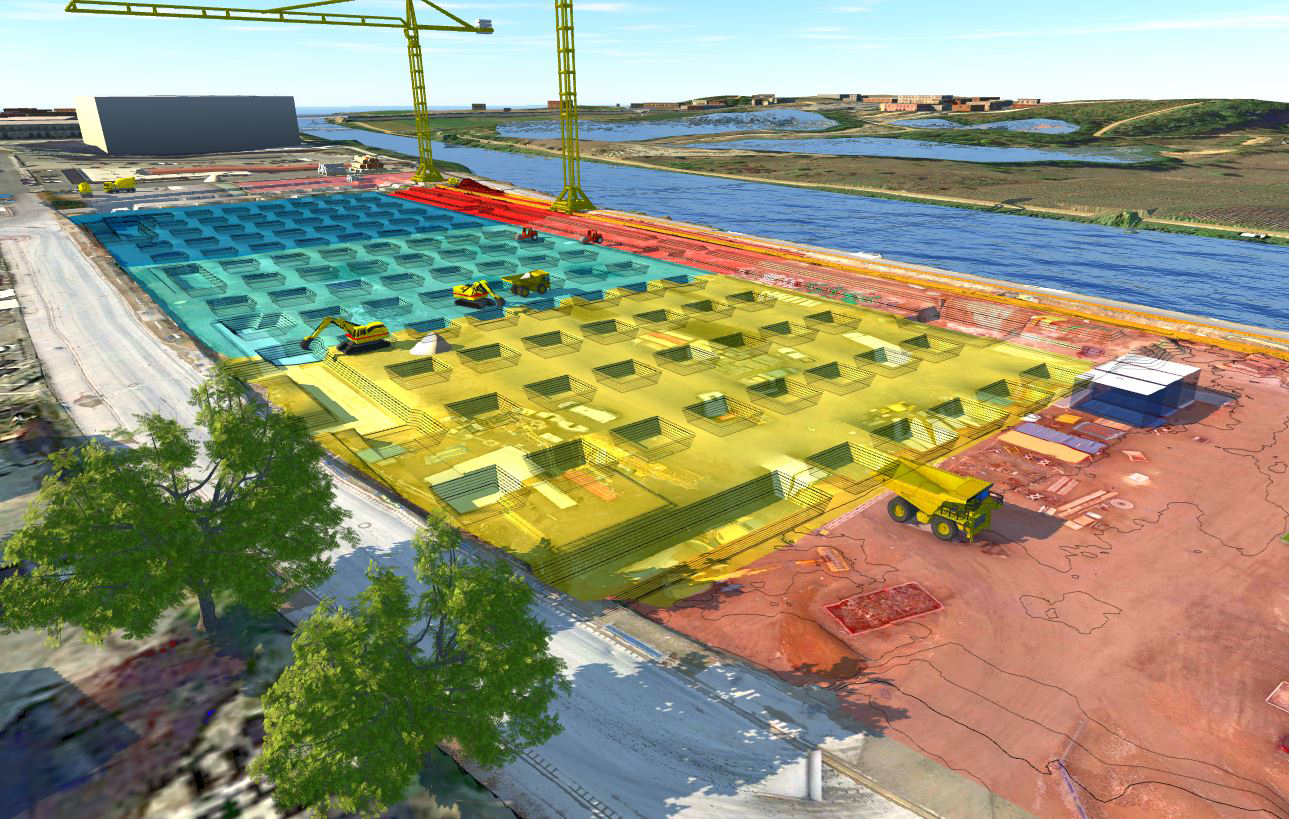

During the execution phase, BIM Excellence provides assistance to the construction site team in evaluating and conducting quantity surveys of the construction environment with the aid of drones. The intelligent combination of 3D models and 2D details provides the execution team with targeted and immediate access to the execution details on the construction site.

Adding changes to the BIM model during execution also helps create reliable as-built documentation. This is made available to the client and helps facilitate model-based defect management. Model-based construction workflow simulations are used to optimise the building process.