- News

- BMW Plant Munich

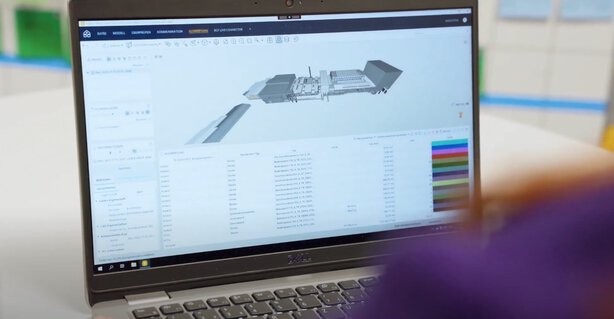

Plan digitally, build optimally - BIM makes it possible

As part of the conversion of the BMW Group's main plant in Munich, we are relying on end-to-end digital processes - with Building Information Modeling as the central tool.

In concrete terms, this means that all project participants work together in a digital twin - the central model that is always up-to-date and brings together all relevant information. For maximum transparency, optimum coordination and the best possible collaboration.

Inconsistencies between planning statuses or collisions between components are detected at an early stage before they lead to problems and delays on the construction site. This not only significantly increases planning reliability, but also promotes close, coordinated collaboration between all parties involved - from design to implementation.

A particular added value: the existing building was also mapped in the BIM model in order to capture important information during demolition. For example, pollutants could be localized in advance, demolition quantities determined and disposal to the respective landfills planned based on this - a decisive step for sustainable and safe project execution.