- News

- Currently with the Siemens TC HEP project

Georeferencing and laser scans in the BIM process

For some time now, there has been a lot of talk in the construction industry of the huge potential and value added that comes from applying BIM methods in the course of digitalisation.

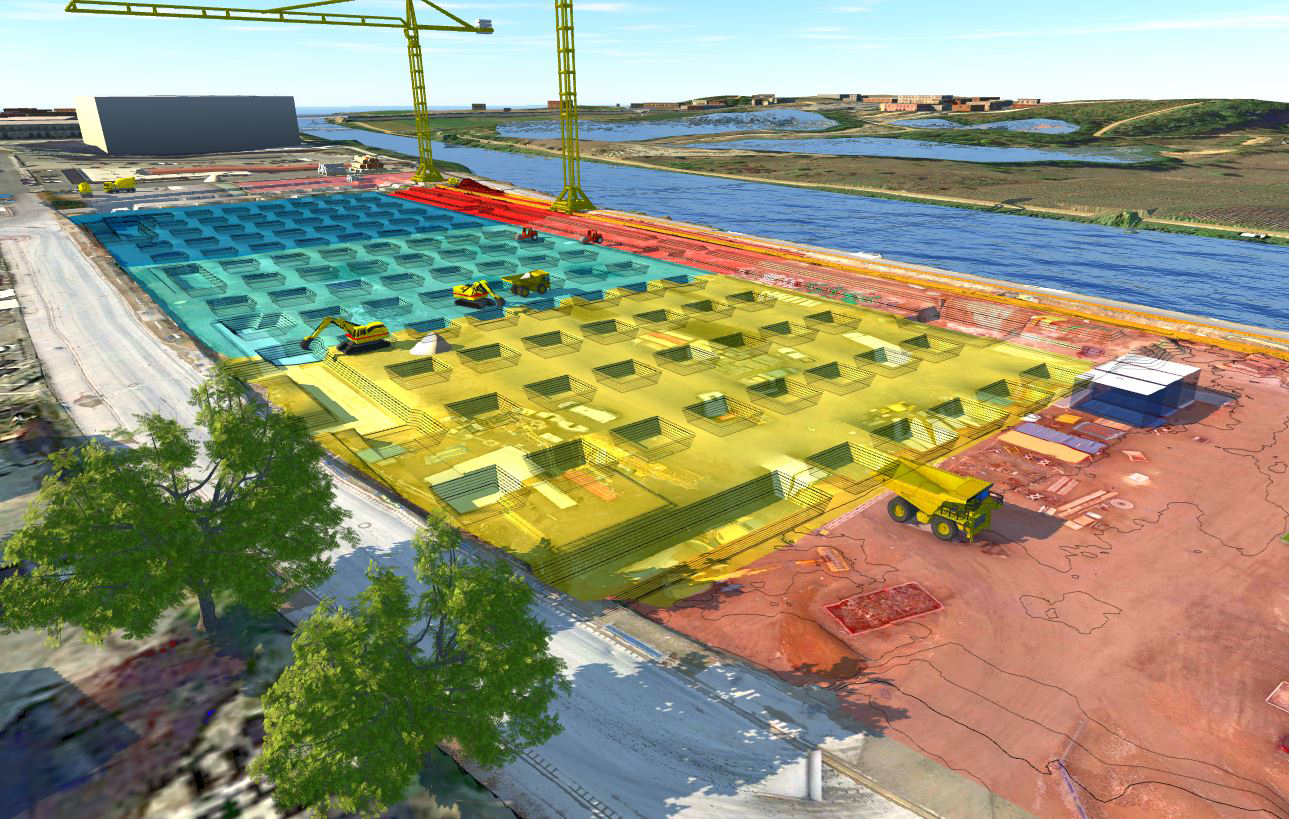

Proof of the potential that can actually be exploited by digitalising construction sites is now visible in multiple recent projects realised by PORR Industriebau GmbH and the BIM Management team of pde Integrale Planung. The use of georeferenced laser scans delivered by drone flights and their integration into the BIM process is now just as common on construction sites as GPS-assisted measurement and determining excavation details using GPS vehicle control.

The basic prerequisite for using these “new” options is consolidating an array of different data and preparing it for subsequent application.

Data needed for the application

Drone recordings

Drones have become a common site hovering over many construction sites for a while now and are used as a tool for different applications. The two most important are documenting the construction progress made via video or photo functions on the one hand and using the drone for surveying purposes such as laser scans or photogrammetry on the other.

Laser scan and point cloud

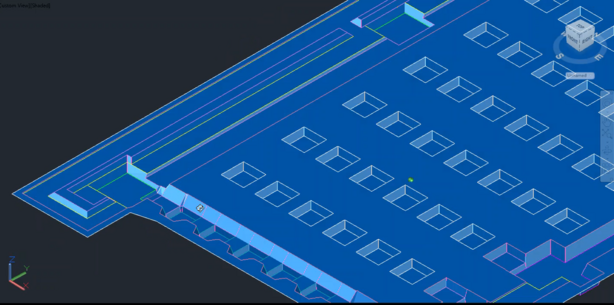

If a laser scan is being conducted, then the images taken by the surveying drone need to deliver a certain level of quality. Here, a laser is used to scan the surface of the terrain by creating a large number of points on the surface that contain information on the coordinates – these are then displayed in the form of a point cloud. The images, in their designated format, are then sent to the technical experts for further processing. Appropriate software solutions allow the points to be connected to form a surface, thereby producing a BIM-capable model of the terrain.

Use of the BIM model

The BIM model is developed in parallel. Collaboration on the 3D model ultimately leads to the consolidated design and planning of the foundation, substructure and underground pipes. The resulting BIM data is prepared in accordance with specification for use in end devices such as GPS rods and excavators with GPS machine control. The precise positioning is determined using the digital model of the terrain and the geodata related to the BIM models, which has already been produced in line with the specs on survey planning.

The prerequisite here is the selective compilation of the BIM data needed for the application in the appropriate format as well as good cooperation between those involved in planning, execution and surveying using common coordinates and coordination systems like UTM and Gauss-Krüger. If these and other detailed requirements have been

Application on the construction site

Once the contractor has applied the data in the designated system, e.g. in an excavator with GPS machine control, the operator uses the BIM data to start on the precise and efficient excavation for underground cabling, foundations, and pipes. Using the GPS rod, the coordinates that were generated in the BIM model with the help of the digital terrain model and then transmitted can be reliably measured on the construction site.

Challenges

The challenges related to using this example of BIM are essentially the same as with any use of the BIM method in the overall process, namely a large number of interfaces between stakeholders. This challenge can be mitigated if everyone involved in the BIM process pulls together. The exemplary management of the colleagues on the construction site who serve as the pivotal point in the execution have proven their value here, as has the intensive support by our team of BIM Management experts from pde.