LEAN Construction

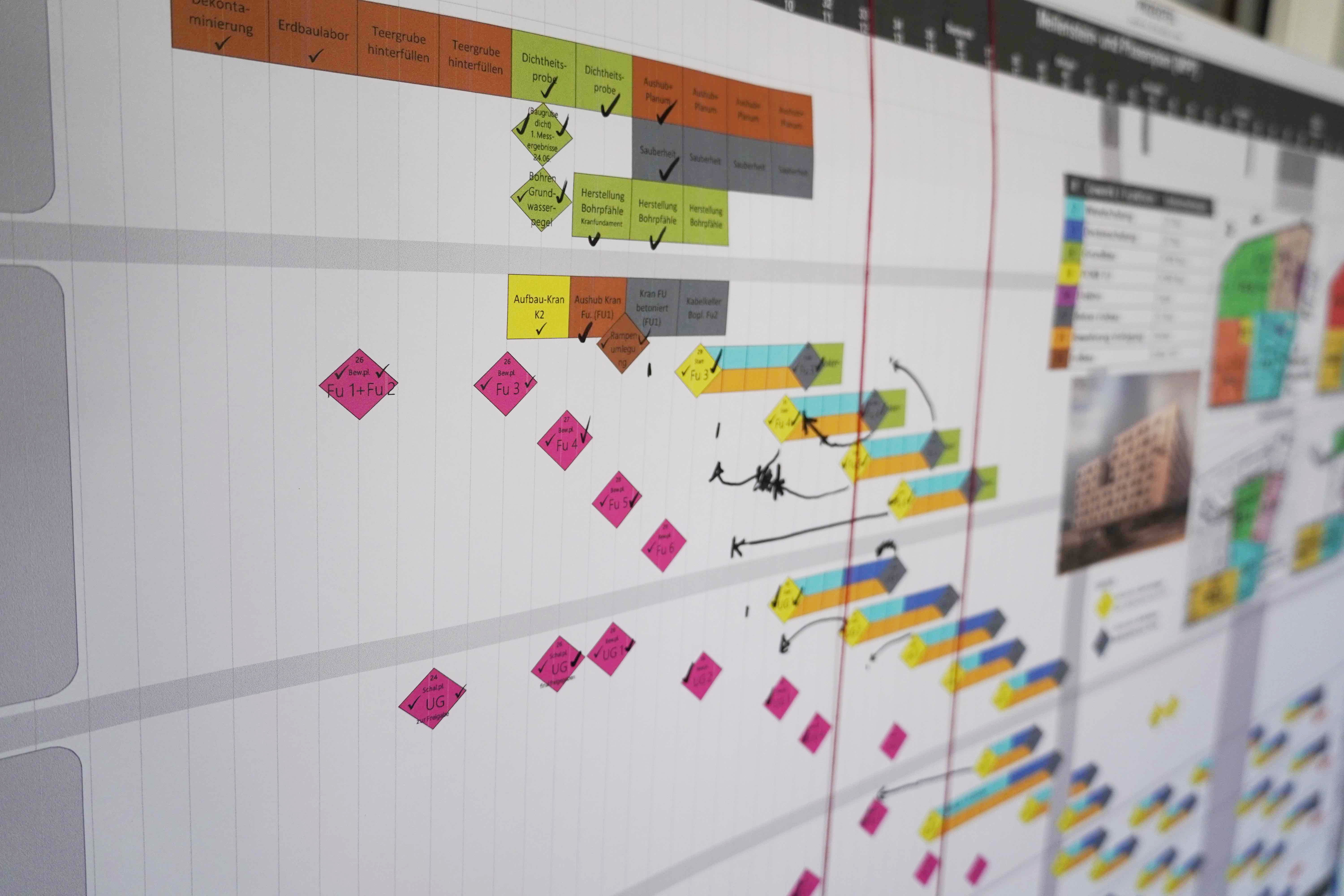

We use LEAN Construction to build sustainable improvements in results and boost client and user satisfaction. We pay particular attention to avoiding and eliminating waste on the construction site during the execution stage. LEAN techniques help us improve efficiency and continuously improve, based on actual analyses and evaluation. The result? We save time (shorter construction periods) and save money.

In order to achieve our results, we work hard to transfer our LEAN Design techniques seamlessly into LEAN Construction methods. Important decisions for the project are made at an early stage, so that we can ensure every preparation is in place at the start of the execution stage. The centre of action is relocated directly to the construction site. This approach avoids segregation between different technical teams – instead, everyone involved is an active participant right from the start.

Site manager

Manager and painter

Foreman HVAC

Foreman and painter

Construction technician

Electrical foreman

Foreman

An efficient construction site

Our portfolio of services in the LEAN Construction stage includes:

- Employee training – theory, methods & tools during the implementation stage

- Project support and weekly evaluations

- Workshops

- Conflict and problem-solving coaching

Are you interested in slimming down workflows for your next construction project?

Get in touch with our expert