BMW Munich Freimann

Savings of EUR 10 million achieved and approval planning completed within 6 weeks: these results were made possible by LEAN Management and the excellent teamwork of pde for the new BMW location in Munich Freimann.

The successful completion of this challenging task not only secured us the general planning contract, but also subsequently earned PORR the contract to construct the office building. pde relied entirely on LEAN management to streamline processes from the start.

Client

Bayerische Motoren Werke Aktiengesellschaft (BMW AG)

pde service period

09/2016–02/2018

Service areas

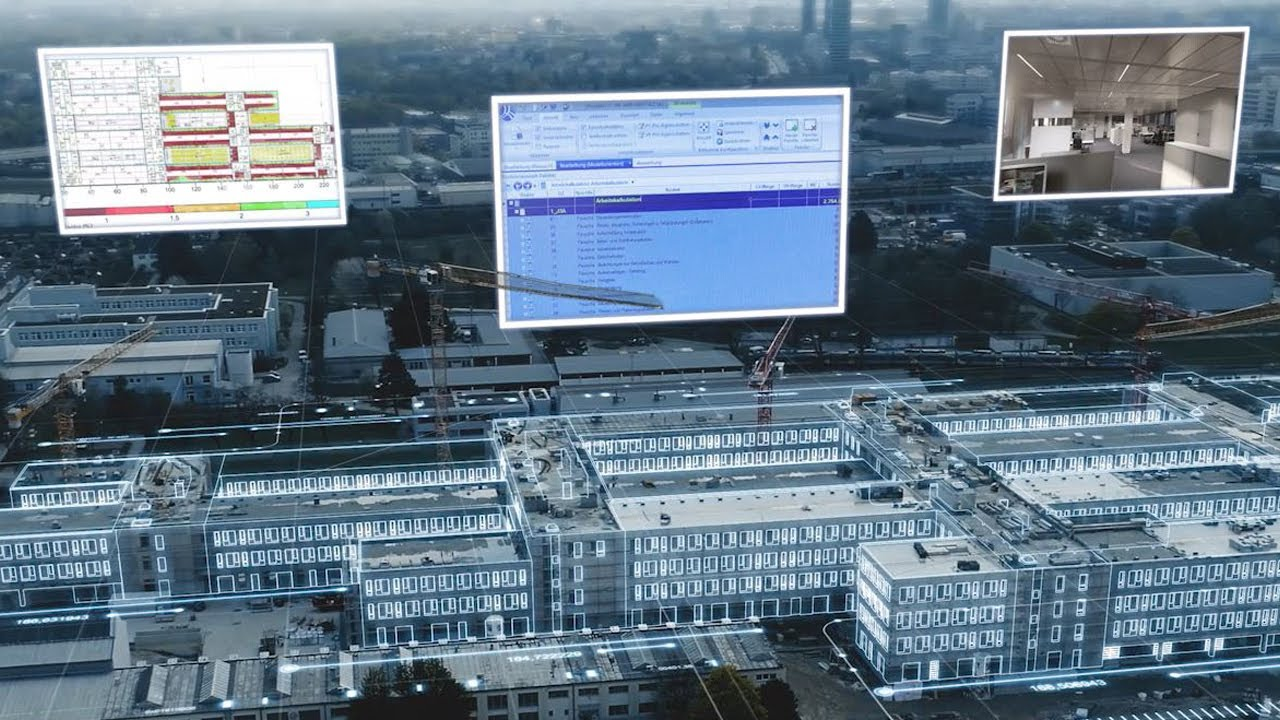

Planning, sustainability, LEAN,BIM

Location

Munich

Completion

08/2019

Dimensions

72,500 m² office space, office building EAST, underground garage (incl. utility and ancillary rooms), catering area, kitchen with cooking islands, conference area, office units, ancillary rooms, fitness studio, multi-storey office modules

Work stage

Work stages 3-5

Partnership provides best performance

A new addition to the BMW site in Freimann, Munich was set to create around 75,000 m2 of new office space by late 2018. As the architects’ plans exceeded the budget by EUR 10 million, pde was awarded a contract following Work phase 2 to identify potential for optimisation in the project and kept it within the set budget. By successfully completing this challenging task, PORR not only secured the contract for general planning work but subsequently also won the contract to erect the office building.

Though use of Building Information Modelling was already an internal company standard, the client also requested it specifically. Indeed, the client had plannedto control building operations using the digital building model and apply BIM in all aspects from the very outset.

In order to streamline processes from the start, pde relied on LEAN Management methods throughout. A key component of this mode of operation was the use of a partnering model involving pde, PORR Bau GmbH and the contractors in the main trades (M&E, facade, interior finishing, building automation). Detailed stage plans and efficient schedule planning using the VILLEGO Last Planner® System made it possible to submit plans for construction approval within a tight timeframe.

‘Future office’ as the focus: from the very outset, pde consciously focused on environmentally-friendly planning, in particular in relation to material selection and water and electricity supplies. The integration of sustainability aspects such as user comfort, material ecology and regional originmeets all the requirements of the ‘sustainable construction’ reference system specified by the BMW-Group.

Teamwork boosts sustainability – thanks to LEAN methods

When pde obtained the contract to complete tasks for Work phase 3, the primary challenge was completing the approval planning on a tight budget within the existing timeframe.

The key to this success? The application of LEAN Management methods. All contracting companies met once a week in the “Big Room” to evaluate progress towards milestones and to identify and counteract delays at an early stage. The communication between key planners and contracting trades sparked new ideas and sustainably improved cooperation. Two workshops over several days saw all project participants come together to develop detailed timescales and milestones, define ground rules for their cooperation and unify different parties’ expectations. The participants also dis- cussed topics such as the future office, smart building, the circular economy and modular construction, putting them in concrete terms for the project.

The client’s representative, Peter Röllgen (BMW), has applied LEAN methods in his work as standard for years. Nevertheless, he was pleasantly surprised by pde.

Peter Röllgen, BMW

"Even though applying LEAN methods was one of our preconditions, we were impressed by how our partner implemented them; this confirmed that pde was the right choice."